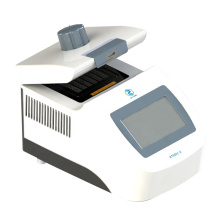

High-intelligent pneumatic thermal conductivity testing equipment / Heat insulation material conductivity testing machine

Información básica

Modelo: ZCY-1A

Descripción del producto

Product Description Automatic high-intelligent pneumatic thermal conductivity testing equipment Thermal conductivity integrated test system is based on design GB/Tl0294-2008 and manufacturing standards for detecting thermal conductivity of insulation materials and special equipment.

Thermal conductivity (or resistance) is one of the main thermal performance of insulation materials. Thermal insulation material is the main symbol of identification of performance quality. In recent years, with the introduction of building energy regulations, China is increasing emphasis on building energy efficiency. Therefore, accurate measurement of the parameters is necessary. It has a great significance for a reasonable selection.

Technical Parameters:

[1] Specimen size 300X300 (mm); the thickness of 10 ~ 40 (mm) (preferably a thickness of 25mm)

[2] Thermal conductivity detection range: 0.001-1.0 (W / (m.K)

[3] Cold plate temperature: 5 °C ~ 50 °C

[4] Hot plate temperature: room temperature: ~ 80 °C

[5] Testing accuracy: ≤2%

[6] Test repeatability: <1%

[7] Power supply voltage AC 220V Total power: 2KW

[8] Use of the environment: the laboratory with air conditioning: 23 ± 2 °C

[9] Size: length × width × height: 800 × 600 × 1600 (mm)

Working Principle:

Thermal conductivity detector uses dual specimen measuring device and guarded hot plate group which includes a heating unit and a cooling unit.

Heating unit is divided of the metering unit in the center and metering units surrounding the protection units separated by the gaps, and equipped with thermal insulation.

The heating unit adopts heater with dual hot sides. The cold plates and the double hot heater surfaces are symmetrically arranged. According to the thickness of the specimen set the mobile cold plate room. The test piece is vertically placed between two parallel plates with a constant temperature. Under the steady state the center measuring section of the test piece has constant heat flow. By measuring one dimensional constant heat flux Q, metering unit area A, the specimen’s cold and hot surface temperature difference △T that flow through metering unit under the steady state, the specimen can be calculated thermal resistance R. Based on the thickness of the specimen it is possible to accurately calculate the thermal conductivity value of the specimen.

The main structural features:

1. Equipment of double specimens, double-sided hot plate, double-sided cold plate ues the world's most advanced polymer materials that has high temperature resisitance, thermal conductivity, softrness and other functions. It can be brought into close contact with the specimen to improve the measurement accuracy of thermal conductivity values.

2. The cooling system uses a closed compressing aggregation. Small running noise, fast cooling speed, long service life and other advantages.

3. The integral cooling method of the cooling unit of thermal conductivity detector and the evaporator not only saves raw materials, but also improves the cooling effect.

4. Clamping specimen is fully automated. Setting the space of mobile cooling unit and thermal unit depending on the thickness of the specimen only needs a single click of setup command on a computer.

5. Microcomputer control system consists of a computer and a printer to complete signal detection, acquisition and processing, temperature control, time control, the state of recovery and printing report.

Promises:

1. Before the purchase we can send specialized technical personnel to design the best processes and proposals.

2. After purchase if you need we can assign technical personnel to install and debug the equipment.

3. One year warranty on the equipment and lifetime maintenance.

4. Perennial supply easy wearing and consumable parts to ensure the long-term use of equipment.

Sales commitment

1. Under customer’s normal storage and transportation, maintenance and use conditions, if equipment can not normally be used due to manufacturing quality, we provide "five packets: warranty, refund, replacement, package delivery, packet disassembly" service. Warranty period is usually one year. According to user’s needs warranty period can be extended.

2. When receipting information about quality feedback, we will quickly deal with it, or rush to the scene to deal with the problem until the normal operation of the equipemnt. Then we analyze the causes and define responsibilities.

3. Our factory provides the necessary technical documentation, product certificates and other relevant documents before the products leaving the factory.

4. To provide spare parts, installation,debugging, maintenance and technical training in time according to customer’s needs.

Company introduction Contact

Thermal conductivity (or resistance) is one of the main thermal performance of insulation materials. Thermal insulation material is the main symbol of identification of performance quality. In recent years, with the introduction of building energy regulations, China is increasing emphasis on building energy efficiency. Therefore, accurate measurement of the parameters is necessary. It has a great significance for a reasonable selection.

Technical Parameters:

[1] Specimen size 300X300 (mm); the thickness of 10 ~ 40 (mm) (preferably a thickness of 25mm)

[2] Thermal conductivity detection range: 0.001-1.0 (W / (m.K)

[3] Cold plate temperature: 5 °C ~ 50 °C

[4] Hot plate temperature: room temperature: ~ 80 °C

[5] Testing accuracy: ≤2%

[6] Test repeatability: <1%

[7] Power supply voltage AC 220V Total power: 2KW

[8] Use of the environment: the laboratory with air conditioning: 23 ± 2 °C

[9] Size: length × width × height: 800 × 600 × 1600 (mm)

Working Principle:

Thermal conductivity detector uses dual specimen measuring device and guarded hot plate group which includes a heating unit and a cooling unit.

Heating unit is divided of the metering unit in the center and metering units surrounding the protection units separated by the gaps, and equipped with thermal insulation.

The heating unit adopts heater with dual hot sides. The cold plates and the double hot heater surfaces are symmetrically arranged. According to the thickness of the specimen set the mobile cold plate room. The test piece is vertically placed between two parallel plates with a constant temperature. Under the steady state the center measuring section of the test piece has constant heat flow. By measuring one dimensional constant heat flux Q, metering unit area A, the specimen’s cold and hot surface temperature difference △T that flow through metering unit under the steady state, the specimen can be calculated thermal resistance R. Based on the thickness of the specimen it is possible to accurately calculate the thermal conductivity value of the specimen.

The main structural features:

1. Equipment of double specimens, double-sided hot plate, double-sided cold plate ues the world's most advanced polymer materials that has high temperature resisitance, thermal conductivity, softrness and other functions. It can be brought into close contact with the specimen to improve the measurement accuracy of thermal conductivity values.

2. The cooling system uses a closed compressing aggregation. Small running noise, fast cooling speed, long service life and other advantages.

3. The integral cooling method of the cooling unit of thermal conductivity detector and the evaporator not only saves raw materials, but also improves the cooling effect.

4. Clamping specimen is fully automated. Setting the space of mobile cooling unit and thermal unit depending on the thickness of the specimen only needs a single click of setup command on a computer.

5. Microcomputer control system consists of a computer and a printer to complete signal detection, acquisition and processing, temperature control, time control, the state of recovery and printing report.

Promises:

1. Before the purchase we can send specialized technical personnel to design the best processes and proposals.

2. After purchase if you need we can assign technical personnel to install and debug the equipment.

3. One year warranty on the equipment and lifetime maintenance.

4. Perennial supply easy wearing and consumable parts to ensure the long-term use of equipment.

Sales commitment

1. Under customer’s normal storage and transportation, maintenance and use conditions, if equipment can not normally be used due to manufacturing quality, we provide "five packets: warranty, refund, replacement, package delivery, packet disassembly" service. Warranty period is usually one year. According to user’s needs warranty period can be extended.

2. When receipting information about quality feedback, we will quickly deal with it, or rush to the scene to deal with the problem until the normal operation of the equipemnt. Then we analyze the causes and define responsibilities.

3. Our factory provides the necessary technical documentation, product certificates and other relevant documents before the products leaving the factory.

4. To provide spare parts, installation,debugging, maintenance and technical training in time according to customer’s needs.

Company introduction Contact

Grupos de Producto : Equipo de prueba

Premium Related Products

Otros productos

Productos hot

Tubería de polietileno de tubo de HDPE PE100 PN10 PN 16 Tuberías de plástico de agua de HDPE negro precioProceso de tratamiento biológico Tratamiento subterráneo de aguas residuales domésticasAnalizador de contenido de shot de lana mineralResina de epoxy del producto de FRPDepurador de gas industrial con filtro de gas FRPMáquina prensadora hidráulica SMC más vendidaPerfil de FRP Perfiles de fibra de vidrioFrp pultrusion morirFiltro de la torre de enfriamiento, relleno de Pvc de la torre de enfriamientoAHU, unidad de ventilación de aire fresco con rueda giratoriaFRP Molded Grating de alta resistencia FRP Grating para la planta químicaRebar Fibra de vidrio FRP / Rebar de plástico concreto FRP RebarMáquina de bobinado de tubo / tubo de Frp que hace la máquinaRecipiente a presión FRP tanque frpTanque de almacenamiento de agua seccional FRPLa máquina más popular de la pultrusión del perfil de FRP de la fibra de vidrio de la fibra de vidrio anticorrosión